Understanding the Basics of Good Earthing

Have you ever wondered why earthing is crucial in electrical systems? It’s like giving your home’s electrical setup a solid foundation. Earthing ensures that excess electrical currents have a safe path to the ground, preventing electrical shocks and equipment damage.

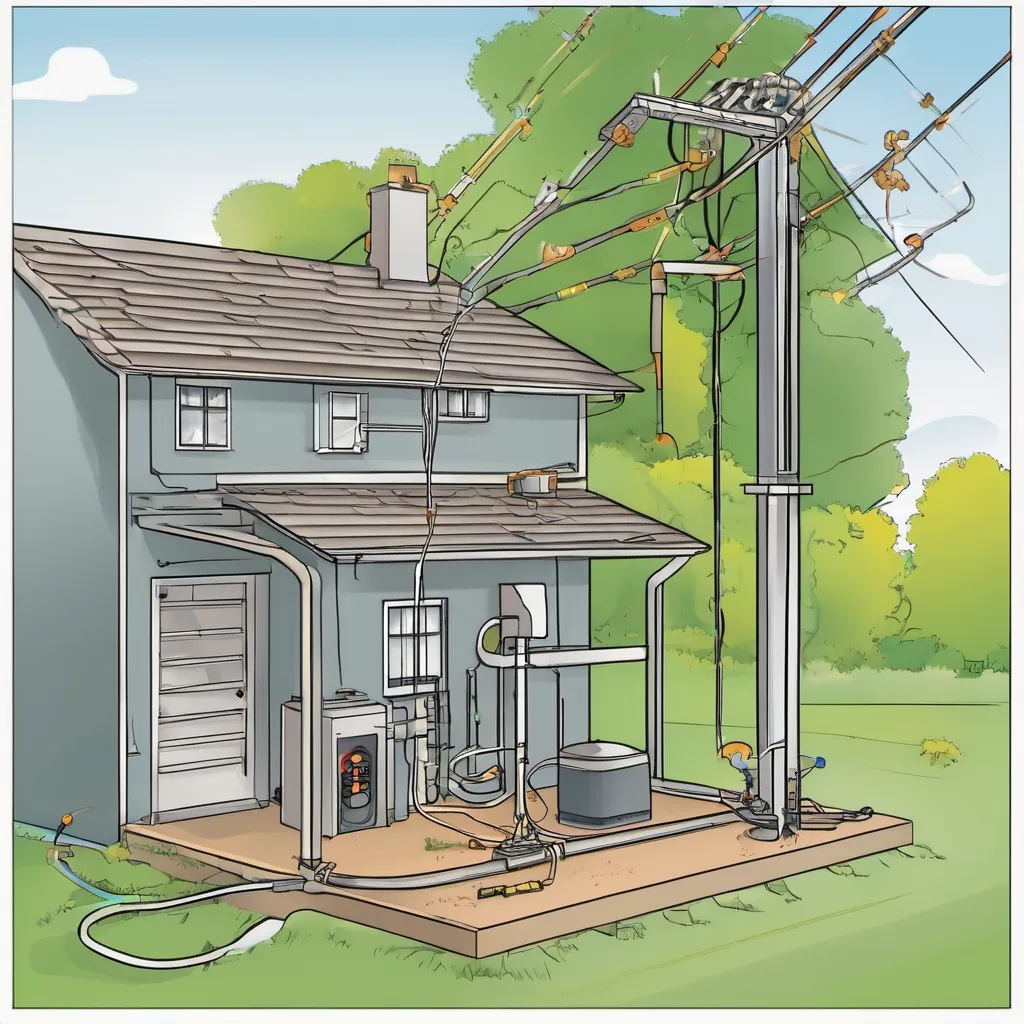

Choosing the Right Grounding Method

There are different methods to achieve good earthing, such as using grounding rods, plates, or grids. The method you choose depends on factors like soil type, moisture levels, and the electrical load of your system. Consulting with an expert can help you determine the best approach for your setup.

Installing Grounding Components Correctly

Once you’ve chosen the grounding method, it’s essential to install the grounding components correctly. Grounding rods should be driven deep into the soil, preferably in a location with good moisture content. Proper connections between grounding conductors and equipment ensure a reliable earthing system.

Regular Maintenance and Inspections

Like any other aspect of your electrical system, good earthing requires regular maintenance and inspections. Periodically check grounding rods for corrosion or damage and ensure all connections are secure. An annual inspection by a qualified electrician can catch potential issues early and keep your earthing system in top shape.

Addressing Common Earthing Problems

Sometimes, despite your best efforts, such problems can still occur. Common issues include high resistance in the earth connection, poor soil conductivity, or inadequate grounding components. Identifying and addressing these problems promptly is crucial to maintaining robust grounding.

The Role of Lightning Protection

In addition to protecting against electrical shocks, strong grounding plays a vital role in lightning protection. A well-grounded system can safely dissipate lightning strikes, reducing the risk of damage to your property and electronics. Make sure your system is up to par, especially in areas prone to lightning strikes.

Educating Yourself and Others

Lastly, don’t underestimate the power of education when it comes to good earthing. Teach your family members or colleagues about the importance of earth and how to recognize signs of earth problems. Encourage them to report any electrical issues promptly to prevent safety hazards.

In conclusion, achieving effective grounding in electrical systems is essential for safety and performance. By understanding the basics, choosing the right grounding method, installing components correctly, conducting regular maintenance, addressing common problems, prioritizing lightning protection, and educating yourself and others, you can ensure a reliable and safe earthing system for your home or business.