These are voltage stabilizers which involves a ‘synchronizing servo motor’ mechanism that helps it to achieve constant power supply whenever there are any fluctuations in the supply.

It is extremely easy to understand the working principle of servo stabilizer.

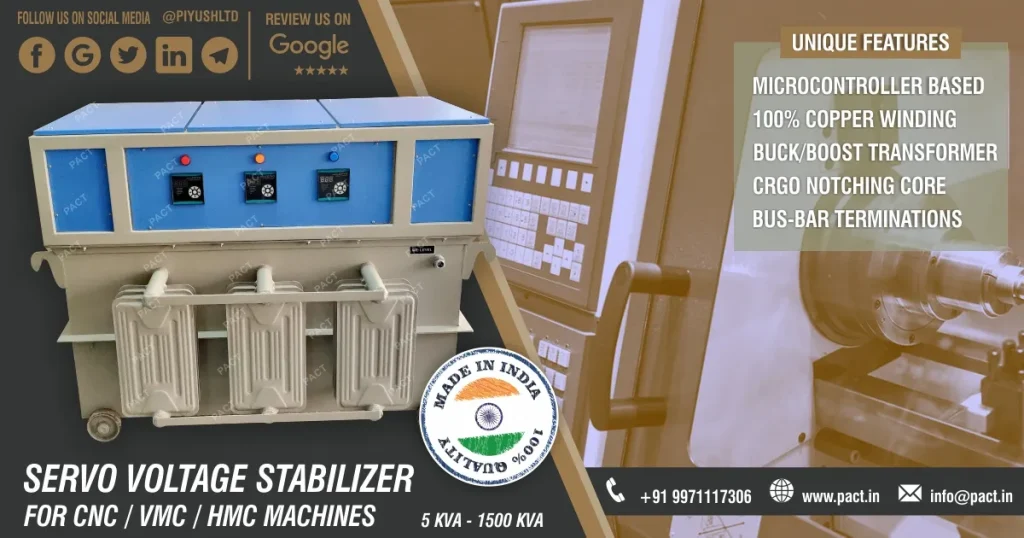

There is an electronic control (PCB) circuit which contains a microcontroller that keeps on monitoring the output voltage. Based on the fluctuations, the regulator triggers the servo motor. The motor rotates the shaft in either clockwise or anti-clockwise direction. The shaft is in turn connected with the auto transformer using a carbon brushes. The output of dimmer is further connected to buck-boost transformer which finally increases or decreases the voltage levels. This process takes place till stable output voltage is achieved.

Features

- Fully programmable with microServo

- Mitered CRGO notching core

- 100% Copper Windings

- With buck/boost transformer (BBT)

- All terminations on bus bar

- Designed, Developed and Made in India

Applications

The application of the servo voltage stabilizer is vast and hence it’s the most important part of commercial industries. Here is some of its application.

- CNC machines

- Hospitals

- AC motors

- Petrol pumps

- Lathe Machine

- Laboratory equipment

- Signaling radars

- Telecommunication exchanges

- Air conditioning plants

- Escalators and elevators

- Offset printing machines

- Medical equipment