The Importance of Understanding Dielectric Strength

Let’s dive into the fascinating world of dielectric strength and why it’s crucial for anyone involved in electrical systems and learn the tips and tricks for breakdown voltage test of transformer oil.

Understanding Dielectric Strength

Dielectric strength refers to the ability of an insulating material to withstand electric stress without breaking down. In simpler terms, it’s like the superhero shield protecting your electrical equipment from voltage fluctuations.

Why It Matters

Picture this: you’re in the middle of an important task when suddenly, zap! Your equipment fries due to a voltage surge. Not fun, right? Understanding dielectric strength helps prevent such mishaps by ensuring your equipment can handle the voltage it’s subjected to.

The Consequences of Ignorance

Imagine not knowing the dielectric strength of your transformer oil. It’s like driving blindfolded on a bumpy road – you’re bound to hit something eventually. Ignorance of dielectric strength can lead to equipment failure, downtime, and costly repairs.

The Role of breakdown voltage test of transformer oil

Now, let’s zoom in on the role of dielectric strength in transformer oil. Transformer oil isn’t just any oil; it’s the lifeblood of your electrical transformers, keeping them cool and insulated. But here’s the kicker: it needs to withstand high voltages without breaking down.

Testing Transformer Oil

Enter the breakdown voltage test of transformer oil. This test measures the dielectric strength of the oil, ensuring it can handle the voltage stresses it’s subjected to in operation. Think of it as a health check for your transformer oil, ensuring it’s up to the task.

Preventing Catastrophes

Imagine the horror of a transformer malfunction due to inadequate dielectric strength in the oil. It’s like a domino effect – one small failure leads to a chain reaction of chaos. By conducting breakdown voltage tests, you’re proactively preventing such catastrophes and ensuring smooth operations.

The Bottom Line

In the world of electrical systems, knowledge is power – quite literally. Understanding the fundamentals of dielectric strength and its importance in transformer oil is key to maintaining reliable and efficient operations. So, don’t underestimate the power of a simple breakdown voltage test. It could save you from a world of trouble.

Unlocking the Secrets: Key Parameters Affecting breakdown voltage test of transformer oil

Let’s take a peek under the hood of transformer oil performance and discover the key parameters that make or break its effectiveness.

1. Moisture Content: The Sneaky Culprit

Moisture content in transformer oil is like that uninvited guest at a party – it wreaks havoc without warning. Even small amounts of moisture can degrade the oil’s dielectric properties, increasing the risk of breakdowns.

2. Acidity Level: The pH Balancing Act

Just like maintaining the pH balance in your swimming pool, keeping the acidity level of transformer oil in check is crucial. High acidity accelerates oil degradation, leading to corrosion and decreased performance.

3. Contaminant Control: Keeping It Clean

Think of transformer oil as a gourmet dish – any contaminants can spoil the flavor. Dirt, dust, and other impurities can compromise the oil’s dielectric strength, making it more prone to breakdowns.

Navigating the Maze: Understanding the Impact

Now that we’ve identified the key parameters affecting transformer oil performance, let’s delve deeper into their impact and how they influence the breakdown voltage test of transformer oil.

Moisture Content: The Silent Saboteur

Picture this: your transformer oil is contaminated with moisture, but you’re none the wiser. As the moisture content increases, the dielectric strength of the oil decreases, making it more susceptible to breakdowns during operation. But fear not! By regularly monitoring and controlling moisture levels, you can ensure your transformer oil stays in top-notch condition.

Acidity Level: Taming the Acid Monster

Ah, acidity – the silent menace lurking in your transformer oil. If left unchecked, high acidity can wreak havoc on your equipment, leading to premature aging and costly repairs. But fret not! By testing the acidity level and neutralizing any acidic compounds, you can keep your transformer oil in tip-top shape and avoid nasty surprises down the line.

Contaminant Control: The Cleanliness Crusade

Imagine your transformer oil is contaminated with dirt and debris, like a muddy puddle after a rainstorm. Not only does it look unsightly, but it also poses a serious threat to your equipment’s performance. By implementing strict contamination control measures and regularly filtering the oil, you can ensure a clean and healthy environment for your transformers to thrive.

In Conclusion: Mastering Transformer Oil Performance

In the high-stakes world of transformer operations, understanding the key parameters affecting oil performance is essential for success. By keeping moisture content, acidity levels, and contaminants in check, you can ensure your transformer oil remains in peak condition and passes the breakdown voltage test with flying colors. So, embrace the power of knowledge and take control of your transformer oil performance today!

Mastering Dielectric Properties: Best Practices Unveiled

Let’s embark on a journey to uncover the best practices for enhancing dielectric properties and ensuring optimal performance of transformer oil.

1. Regular Testing: The Foundation of Success

Picture this: you’re embarking on a road trip, but you forget to check your car’s oil levels. Disaster, right? Similarly, regular testing is the cornerstone of maintaining optimal dielectric properties in transformer oil. By conducting routine breakdown voltage tests, you can identify any issues early on and take corrective action before they escalate.

2. Proper Maintenance: The Key to Longevity

Just like your favorite houseplant, transformer oil thrives when given proper care and attention. Regular maintenance, including filtration and purification, helps remove contaminants and extends the oil’s lifespan. Think of it as giving your oil a spa day – rejuvenating and refreshing for peak performance.

3. Temperature Control: Keeping Cool Under Pressure

Imagine your transformer oil as a delicate flower, wilting under the scorching sun. Excessive heat can degrade the oil’s dielectric properties, increasing the risk of breakdowns. By implementing temperature control measures, such as cooling systems or insulation, you can ensure your oil stays cool and collected even under pressure.

Nurturing Dielectric Properties: Practical Tips and Tricks

Now that we’ve uncovered the best practices for enhancing dielectric properties, let’s delve deeper into some practical tips and tricks to help you master the art of transformer oil maintenance.

Regular Testing: Don’t Skip Your Check-ups

Just like visiting the dentist or getting your car serviced, regular testing is non-negotiable when it comes to maintaining optimal dielectric properties. Schedule routine breakdown voltage tests to assess the oil’s condition and identify any potential issues before they spiral out of control.

Proper Maintenance: Treat Your Oil Like Royalty

Your transformer oil deserves the royal treatment, so don’t skimp on maintenance. Invest in regular filtration and purification to remove contaminants and prolong the oil’s lifespan. Think of it as giving your oil a spa day – pampering it to perfection for peak performance.

Temperature Control: Keep Your Cool

Maintaining the right temperature is crucial for preserving dielectric properties. Implement cooling systems or insulation to shield your oil from excessive heat and ensure it stays cool under pressure. Think of it as providing shade on a hot summer day – keeping your oil cool and collected when it matters most.

In Conclusion: Elevating Dielectric Properties to New Heights

In the world of transformer operations, mastering dielectric properties is the key to success. By following best practices such as regular testing, proper maintenance, and temperature control, you can ensure your transformer oil remains in peak condition and passes the breakdown voltage test with flying colors. So, embrace these tips and tricks, and elevate your oil to new heights of performance today!

Streamlining Maintenance: Integrating Oil Test Sets Into Your Routine

Let’s explore the seamless integration of oil test sets into your routine maintenance schedule and how it can revolutionize your transformer operations.

1. The Power of Proactivity: Making Testing a Habit

Imagine if you only brushed your teeth when they started hurting – not the best idea, right? Similarly, integrating oil test sets into your routine maintenance schedule ensures proactive monitoring of transformer oil health. By making testing a habit, you can catch potential issues early and avoid costly downtime.

2. Simplifying Your Schedule: Setting Regular Testing Dates

Life is hectic enough without adding more to your plate, right? That’s why setting regular testing dates for your oil test sets can simplify your maintenance schedule. Whether it’s monthly, quarterly, or annually, having a consistent testing regimen ensures no oil-related surprises catch you off guard.

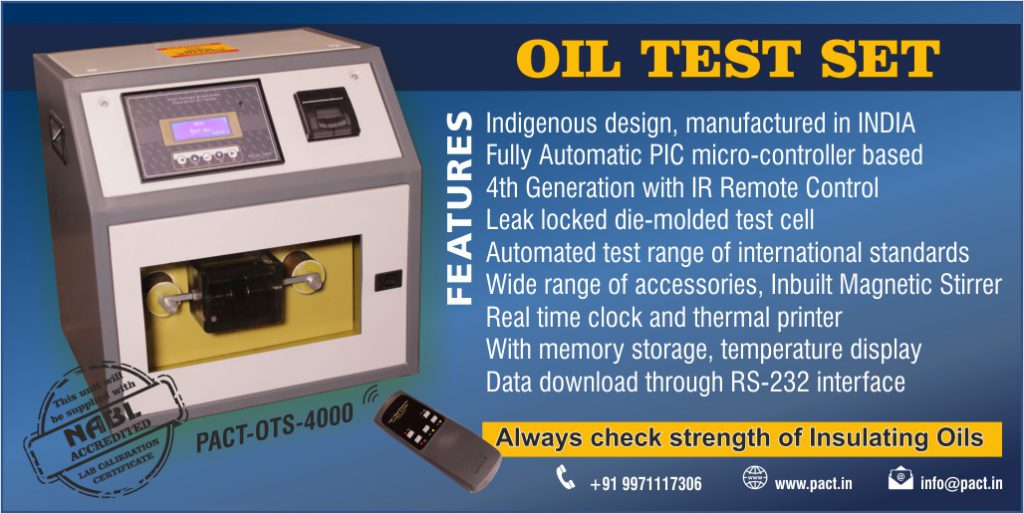

3. The Benefits of Automation: Taking the Workload Off Your Shoulders

Let’s face it – we could all use a little help now and then. Automating oil testing with test sets takes the workload off your shoulders, allowing you to focus on more pressing matters. With automated testing, you can set it and forget it, knowing your oil’s health is being monitored round the clock.

Embracing Efficiency: Integrating Oil Test Sets Into Your Routine

Now that we understand the importance of integrating oil test sets into your routine maintenance schedule, let’s explore how to do it effectively for maximum efficiency.

The Power of Proactivity: Stay Ahead of the Game

Don’t wait for problems to rear their ugly heads – be proactive and stay ahead of the game by integrating oil test sets into your routine maintenance schedule. Regular testing allows you to catch potential issues early, preventing costly downtime and keeping your operations running smoothly.

Simplifying Your Schedule: Make Testing a Habit

Life is busy enough without adding more to your plate, so simplify your maintenance schedule by setting regular testing dates for your oil test sets. Whether it’s weekly, monthly, or annually, having a consistent testing regimen ensures no surprises catch you off guard.

The Benefits of Automation: Let Technology Work for You

Why do things the hard way when you can let technology do the heavy lifting for you? Automating oil testing with test sets takes the workload off your shoulders, allowing you to focus on more pressing matters. With automated testing, you can set it and forget it, knowing your oil’s health is being monitored round the clock.

In Conclusion: Mastering Routine Maintenance with Oil Test Sets

In the fast-paced world of transformer operations, integrating oil test sets into your routine maintenance schedule is essential for staying ahead of the curve. By proactively monitoring your oil’s health, simplifying your schedule with regular testing dates, and embracing the benefits of automation, you can ensure your operations run smoothly and efficiently. So, don’t wait for problems to arise – start integrating oil test sets into your routine today and reap the rewards of proactive maintenance!