Preparing for BDV Test of Oil

So, you’re gearing up for a Breakdown Voltage (BDV) test of your transformer oil? Fantastic! Let’s make sure you’re fully prepared for this exciting journey into transformer health.

Gather Your Gear

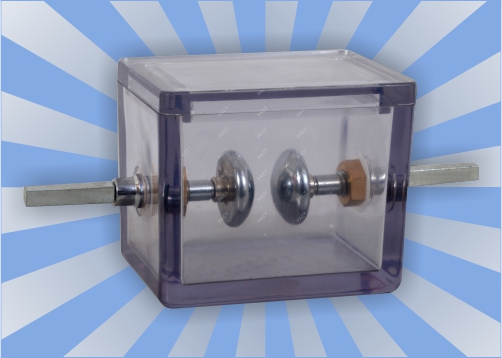

First things first, gather all the necessary equipment for your BDV analysis. You’ll need your BDV test kit, including the testing apparatus, electrodes, and insulating oil samples. Make sure everything is clean and in good working condition. A well-prepared kit is the key to accurate results!

Choose the Right Sample for BDV test of oil

Not all oil samples are created equal. When preparing for BDV analysis, it’s essential to select the right sample from your transformer. Aim for a representative sample that reflects the condition of the entire system. Avoid samples that have been contaminated or diluted, as they can skew your results. Remember, quality over quantity!

Mind Your Environment

Where you conduct your BDV analysis can have a significant impact on the results. Choose a clean, well-ventilated area free from dust and other contaminants. Temperature and humidity can also affect the test, so try to maintain a stable environment throughout the analysis. Think of it as creating the perfect setting for a scientific experiment!

Handle with Care

Transformer oil may not seem like a delicate substance, but it’s essential to handle it with care during the BDV analysis process. Avoid introducing any foreign particles or air bubbles into the sample, as they can interfere with the test results. Use clean, dry equipment and follow proper handling procedures to ensure the integrity of your samples. Treat your oil samples like the precious gems they are!

Stay Calm and Patient

BDV analysis requires a steady hand and a patient mindset. Take your time to set up the test apparatus correctly and follow the procedure meticulously. Rushing through the process can lead to inaccurate results and unnecessary headaches down the line. Remember, good things come to those who wait – especially in the world of transformer maintenance!

Document Everything

Once you’ve completed your BDV analysis, don’t forget to document everything. Record the test conditions, sample information, and, most importantly, the test results. Keeping thorough records will help you track changes in your transformer’s health over time and make informed maintenance decisions. It’s like creating a roadmap to a healthier, happier transformer!

Conclusion

Preparing for BDV analysis may seem like a daunting task, but with the right approach, it can be a rewarding experience. By gathering your gear, choosing the right sample, minding your environment, handling with care, staying calm and patient, and documenting everything, you’ll set yourself up for success. So, roll up your sleeves, put on your lab coat, and get ready to dive into the fascinating world of transformer oil analysis!

Conducting the BDV test of oil – Like a Pro

Ready to dive into conducting your Breakdown Voltage (BDV) test like a seasoned pro? Let’s walk through the process step by step and ensure you get accurate results every time.

Set Up Your Equipment Properly

Before diving into the BDV test, it’s crucial to set up your equipment properly. Ensure that all components of your BDV test kit are assembled correctly and that electrodes are securely in place. A solid setup lays the foundation for reliable results.

Fill Your Sample Chamber Carefully

Next up, it’s time to fill the sample chamber with your transformer oil sample. Take care to pour the oil slowly and steadily, avoiding any spills or splashes. Air bubbles can affect the accuracy of your results, so aim for a smooth and even fill.

Apply the Right Voltage

Now comes the moment of truth – applying the voltage. Be sure to follow the recommended voltage settings for your specific BDV test kit and transformer oil type. Too much or too little voltage can skew your results, so it’s essential to get it just right.

Observe and Record

As the test proceeds, keep a close eye on the electrodes and the oil sample. Look out for any signs of arcing or sparking, as these could indicate issues with the oil’s dielectric strength. Meanwhile, diligently record the test parameters and any observations for future reference.

Be Patient while performing BDV test of oil

BDV testing requires patience and a steady hand. Resist the urge to rush through the test or make hasty adjustments. Instead, take your time, stay focused, and trust in the process. Remember, precision is key when it comes to transformer maintenance.

Repeat for Accuracy

For the most accurate results, consider repeating the BDV test multiple times. This helps to ensure consistency and reliability in your measurements. By averaging the results of several tests, you can minimize the impact of any outliers and gain a more accurate assessment of your transformer oil’s breakdown voltage.

Evaluate Your Results

Once the BDV test is complete, it’s time to evaluate your results. Compare the measured breakdown voltage with the recommended thresholds for your transformer oil type. If the results fall within the acceptable range, congratulations – your oil is in good shape! If not, it may be time to investigate further or consider preventative maintenance measures.

Conclusion

Conducting a BDV test like a pro requires attention to detail, patience, and a steady hand. By setting up your equipment properly, filling the sample chamber carefully, applying the right voltage, observing and recording diligently, being patient and staying calm, repeating for accuracy, and evaluating your results thoughtfully, you can ensure accurate and reliable measurements of your transformer oil’s breakdown voltage. So, roll up your sleeves, put on your safety goggles, and get ready to become a BDV testing master!

Interpreting BDV Results Effectively

So, you’ve just received the results of your Breakdown Voltage (BDV) test, and now you’re wondering what they mean for your transformer oil. Don’t worry; we’ve got you covered! Let’s dive into the world of interpreting BDV results effectively and make sense of those numbers together.

Deciphering the Numbers

First things first, let’s talk about the numbers you see in your BDV test results. This numerical value represents the breakdown voltage of your transformer oil – essentially, the point at which its insulation strength gives way, allowing electricity to flow through. But what does that mean for you and your equipment? Let’s find out!

Comparing to the Norms

Now that you have your BDV result in hand, it’s time to put it into perspective. How does it stack up against industry standards and recommended thresholds? These benchmarks vary depending on factors like oil type and equipment specifications. By comparing your result to these norms, you can gauge whether your oil is performing as it should or if there’s cause for concern.

Spotting Potential Trouble

Sometimes, your BDV result might raise a red flag – and that’s okay! Significant deviations from the expected value could indicate potential issues with your transformer or oil. For instance, a lower-than-expected BDV might suggest oil degradation or contamination, while a higher-than-expected value could signal overprocessing or other factors affecting its dielectric properties. By spotting these deviations early on, you can take proactive steps to address any underlying issues and keep your equipment running smoothly.

Considering External Influences

It’s essential to remember that BDV test results aren’t always cut and dry. External factors like temperature, humidity, and even sample handling can influence the outcome. For example, extreme temperatures can impact the oil’s dielectric strength, leading to skewed results. Likewise, improper sample handling or testing methodology can introduce errors into the process. By taking these external influences into account, you can ensure a more accurate interpretation of your BDV results and make informed decisions about your equipment’s maintenance needs.

Tracking Trends Over Time

One of the most significant benefits of BDV testing is its ability to track trends in your transformer oil’s health over time. By conducting regular tests and comparing the results, you can identify patterns that may indicate changes in the oil’s condition. For example, a gradual decrease in BDV values over multiple tests could signal ongoing degradation, while a sudden spike might point to a recent issue that needs attention. By tracking these trends, you can stay ahead of potential problems and implement preventive maintenance measures to keep your equipment in top shape.

In Conclusion

Interpreting BDV test results effectively is essential for maintaining the health and performance of your transformer oil and equipment. By understanding the numbers, comparing them to industry norms, spotting potential trouble, considering external influences, and tracking trends over time, you can gain valuable insights into your oil’s condition and take proactive steps to ensure the longevity of your equipment. So, the next time you receive your BDV test results, don’t panic – take a deep breath, analyze them carefully, and use them to keep your equipment humming along happily!

Common Mistakes to Avoid in BDV Testing

So, you’re gearing up for a Breakdown Voltage (BDV) test on your transformer oil? That’s fantastic! But before you dive in, let’s chat about some common mistakes you’ll want to avoid to ensure accurate results and smooth sailing.

Skipping Proper Equipment Calibration

One of the biggest blunders in BDV testing is skipping proper equipment calibration. Your BDV test kit needs to be calibrated regularly to ensure accurate readings. Skipping this step can lead to skewed results and unnecessary headaches down the line. So, take the time to calibrate your equipment properly before each test – your transformer will thank you for it!

Ignoring Sample Contamination

Transformer oil samples are like delicate flowers – they need to be handled with care. Ignoring sample contamination is a surefire way to throw off your BDV test results. Make sure your sample containers are clean and free from any contaminants before collecting your oil samples. A little extra effort now can save you a lot of trouble later on.

Rushing Through the Test Process

BDV testing is not a race – it’s a meticulous process that requires patience and attention to detail. Rushing through the test process can lead to errors and inaccurate readings. Take your time to set up the equipment correctly, fill the sample chamber carefully, and apply the voltage accurately. Remember, precision is key when it comes to BDV testing.

Neglecting Environmental Factors

Environmental factors can have a significant impact on BDV test results, so it’s essential not to neglect them. Temperature, humidity, and even altitude can affect the dielectric strength of the oil and skew your readings. Make sure you conduct your BDV test in a controlled environment free from any external influences. Your transformer will thank you for it!

Failing to Document Test Conditions

Documenting test conditions may seem like a tedious task, but it’s essential for ensuring the accuracy and reproducibility of your BDV test results. Be sure to record details such as the test voltage, sample temperature, and any environmental factors that may have influenced the outcome. This information will come in handy when interpreting your results and troubleshooting any issues that arise.

Not Training Personnel Properly

Last but not least, failing to train personnel properly can lead to errors in BDV testing. Make sure anyone involved in conducting BDV tests receives thorough training on proper procedures, equipment handling, and safety precautions. Investing in training now can prevent costly mistakes and ensure consistent, reliable results in the long run.

In Conclusion

Avoiding common mistakes in BDV testing is essential for obtaining accurate results and maintaining the health of your transformer oil and equipment. By calibrating your equipment properly, avoiding sample contamination, taking your time during the test process, considering environmental factors, documenting test conditions, and ensuring personnel are properly trained, you can minimize errors and ensure the reliability of your BDV test results. So, take a deep breath, double-check your procedures, and dive into BDV testing with confidence – your transformer will thank you for it!