Table of contents

Understanding Single-Stage vs. Two-Stage Servo Stabilizer

Servo Voltage stabilizer play a crucial role in protecting electrical equipment from voltage fluctuations, ensuring consistent and reliable performance for better efficiency. There are various designs of stabilizers designed to meet different needs, with single-stage and two-stage being the most common. Understanding the differences between these two is essential for achieving higher efficiency before selecting the right servo stabilizer for specific applications.

Single-Stage Stabilizer (1S)

- Basic voltage regulation in one step.

- Suitable for simple applications with moderate voltage fluctuation tolerance.

- Cost-effective but may lack precision under varying loads.

Two-Stage Stabilizer (2S)

- Advanced arrangement with two distinct voltage correction stages.

- First stage: Buck Boost Transformer (BBT) adjusts input voltage broadly.

- Second stage: Auto Transformer fine-tunes voltage precisely.

- Offers superior stability, efficiency, and accuracy, ideal for critical applications with strict voltage control requirements from your servo stabilizer.

The two-stage (2S) arrangement is particularly beneficial for applications requiring strict voltage control and minimal power losses. It provides superior performance by distributing the voltage correction tasks between two specialized components, thereby enhancing the overall stability and efficiency of the servo stabilizer.

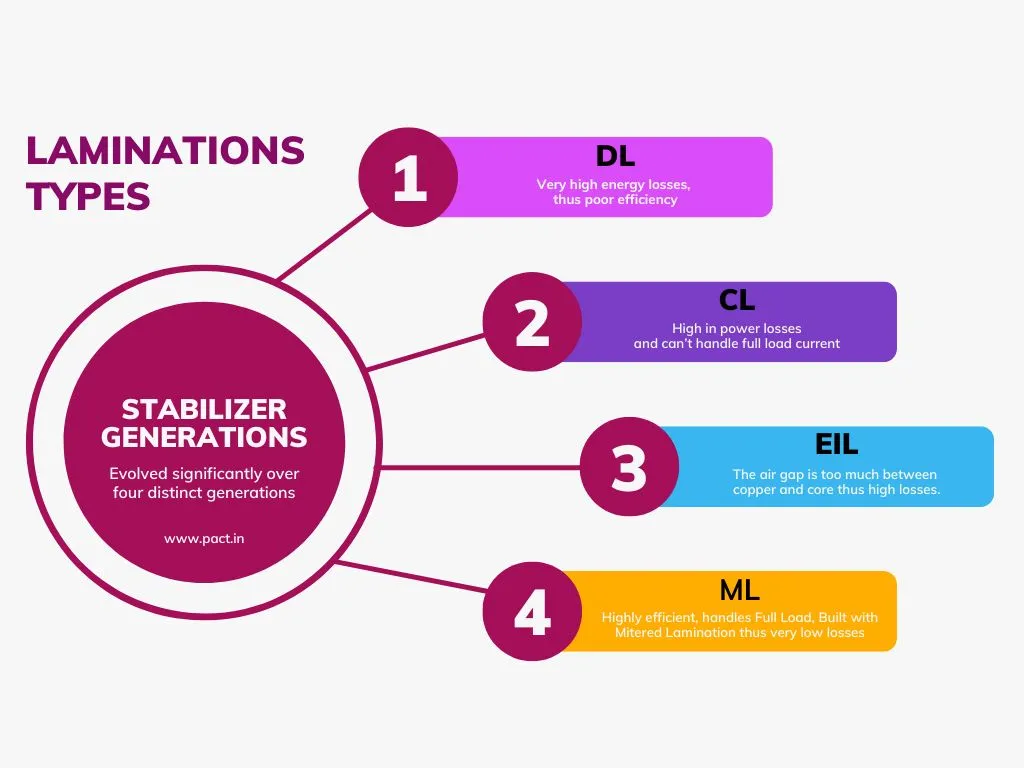

Stabilizer Types Explained: CL, DL, EIL, and ML

Servo stabilizer have evolved significantly over four distinct generations, each marked by technological advancements and tailored functionalities to meet varying voltage regulation needs and better efficiency.

1st Generation | 1-Stage (1S) | BBT on Dimmer Lamination (DL)

The initial generation featured basic single-stage servo stabilizer without a separate Buck Boost Transformer (BBT), providing fundamental voltage regulation. These servo stabilizer offered essential protection against voltage fluctuations, laying the groundwork for subsequent advancements, but not at all good in efficiency.

2nd Generation | 2-Stage (2S) | BBT on Circular Lamination (CL)

Advancing to the second generation, two-stage stabilizers emerged, incorporating a Buck Boost Transformer (BBT) for initial voltage correction and an auto transformer for fine-tuning. In this generation, transformers typically utilized circular lamination, enhancing efficiency and stability in voltage control from your servo stabilizer.

3rd Generation | 2-Stage (2S) | BBT on EI Lamination (EIL)

The third generation introduced further advancements with two-stage servo stabilizer featuring EI lamination in transformers for slight better efficiency. This technology significantly improved magnetic properties, reduced core losses, and enhanced overall efficiency, making these stabilizers ideal for precise voltage control and energy conservation.

4th Generation | 2-Stage (2S) | BBT on Mitered Lamination (ML)

The latest generation represents a leap in stabilizer technology, featuring advanced two-stage arrangements with mitered lamination.

These servo stabilizer leverage cutting-edge technologies like microprocessors and digital control systems for real-time monitoring, adaptive voltage correction, and remote management and best efficiency. The use of mitered laminations ensures optimal performance, minimal energy wastage, and unparalleled precision in voltage stabilization, setting new standards in the industry.

Attention Consumers: Before purchasing a voltage stabilizer, it’s crucial to precheck with the manufacturer regarding the arrangement type (1S or 2S). Additionally, inquire about the generation of the stabilizer’s transformer, such as DL (Dimmer Lamination), CL (Circular Lamination), EIL (EI Lamination), or ML (Mitered Lamination). These factors significantly impact the stabilizer’s efficiency, performance, and suitability for your specific voltage regulation needs.

Being informed about these details ensures that you get the right stabilizer that meets your requirements and delivers optimal voltage control and stability. It also helps in avoiding compatibility issues and ensures a reliable and efficient solution for your electrical system.